The foundational element determining the Electric Handle Milk Frother’s durability is the quality of materials used in both its external structure and internal components. In commercial food service environments where a device may be used dozens—or even hundreds—of times daily, plastic casings commonly found in consumer-grade models often degrade quickly due to repetitive handling, chemical exposure from cleaning agents, or incidental impacts. In contrast, frothers designed for commercial settings feature reinforced ABS plastic or die-cast aluminum alloy bodies, offering superior resistance to thermal stress, physical impact, and fatigue. The whisk or frothing rod is made from high-grade 304 or 316 stainless steel, which is essential not only for resisting corrosion from milk sugars and acids but also for maintaining structural rigidity under constant rotation. These materials help the tool maintain both hygiene and mechanical integrity over prolonged use.

The motor is the operational core of any Electric Handle Milk Frother, and in commercial settings, it must endure far more frequent duty cycles than what is typically expected in a domestic environment. In entry-level consumer models, motors are often designed for intermittent use, and sustained high-volume operation can lead to premature burnout, overheating, or voltage instability. In contrast, commercial-grade models use high-torque, continuous-duty motors, often with integrated thermal protection circuits to prevent overload and burnout. These motors may be either high-efficiency brushed DC types with enhanced carbon brush life or brushless motors, which offer virtually maintenance-free operation and significantly extended lifespans. High-performance frothers incorporate precision-balanced shafts and durable bushings or bearings, minimizing friction and internal wear while ensuring smooth operation even after hundreds of hours of runtime.

Commercial kitchens, cafés, and espresso bars are environments prone to elevated humidity, temperature fluctuations, and exposure to steam or hot liquids. Therefore, any electrical equipment used regularly in these settings must be designed to resist ingress and operational degradation. Durable Electric Handle Milk Frothers feature moisture-resistant seals around buttons, battery or charging ports, and joint seams. Manufacturers often utilize conformal coatings or insulation layers inside the handle or motor housing to shield critical electronic components from humidity-induced corrosion or short circuits. The materials used must remain stable and intact despite frequent temperature swings—both from being used to froth hot milk and from subsequent cleaning with warm water or sanitizing agents. A well-designed frother will continue to perform optimally under these conditions without warping, cracking, or losing motor consistency.

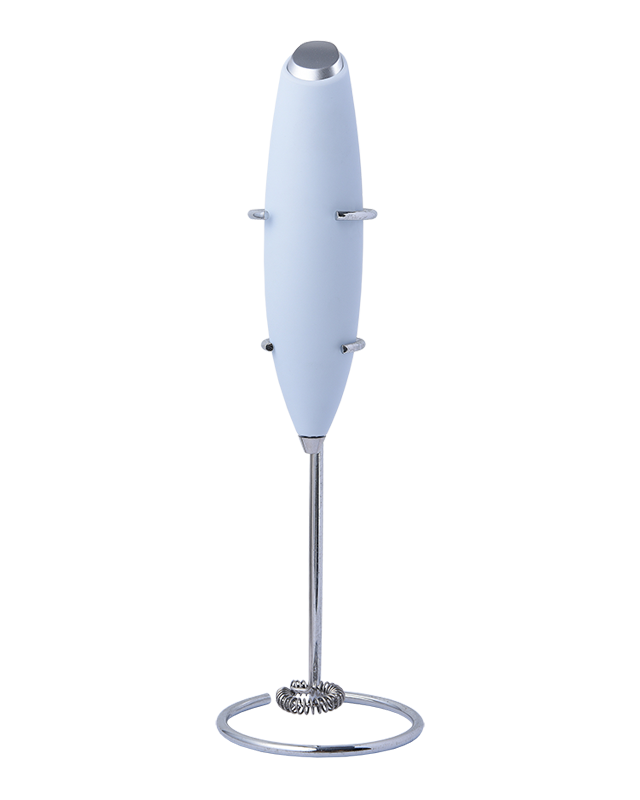

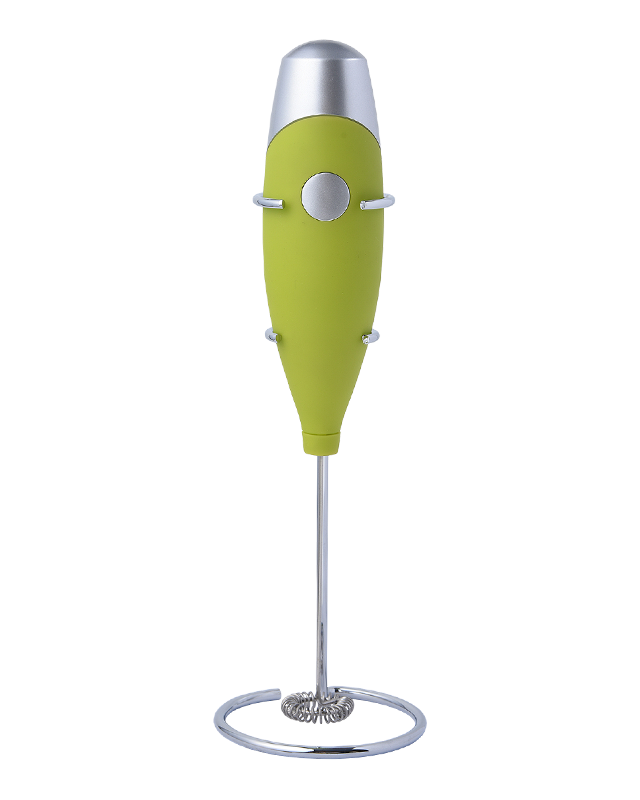

In high-use commercial environments, a tool’s ability to withstand wear and tear from both mechanical stress and operator fatigue is crucial. A durable Electric Handle Milk Frother should not only function mechanically over the long term but must also be ergonomically shaped to facilitate extended usage by baristas or staff members during busy periods. This means contoured handles, balanced weight distribution, anti-slip grips, and easy-access control buttons that can be actuated even with gloved or wet hands. Internally, the frother must incorporate reinforced pivot points, high-durability triggers or switches, and vibration-dampening components to preserve mechanical function across thousands of on-off cycles. Devices that skimp on ergonomic and structural design often suffer from cracking handles, sticking triggers, or detachment of internal parts after months of commercial use.

Durability in a commercial context isn’t just about resisting wear—it’s also about how easily the frother can be cleaned, maintained, or serviced to continue working optimally. High-quality Electric Handle Milk Frothers designed for repeated use are built with modular or accessible designs that allow the whisk attachment to be removed without specialized tools for daily cleaning. More advanced models offer dishwasher-safe components or include included cleaning brushes to simplify sanitation. For long-term operation, the availability of replacement parts—such as frothing heads, gaskets, internal seals, or power adapters—is a critical consideration.

English

English

Français

Français

Español

Español

Deutsch

Deutsch

日本語

日本語