Reducing noise levels in electronic manicure devices can enhance the user experience. Here are some strategies to solve problems related to noise during operation:

Vibration Isolation: Employ advanced engineering techniques to incorporate vibration isolation mechanisms within the device structure. This may include the strategic placement of shock-absorbing materials or the use of isolating mounts to minimize the transmission of vibrations from the motor to the device casing. This approach ensures that operational vibrations do not contribute significantly to the overall noise emitted by the device.

Quality Motor Design: Invest in high-quality, precision motors with superior craftsmanship. Utilize motors that are specifically engineered to operate quietly while maintaining efficiency. This involves rigorous testing of motor components to identify and address potential sources of noise generation, ensuring that the motor design aligns with the desired noise reduction objectives.

Noise Dampening Materials: Integrate noise-dampening materials, such as specialized rubber or silicone compounds, strategically within the device casing. These materials serve to absorb and dissipate vibrations, reducing the overall noise emitted during operation. Careful consideration should be given to the selection and placement of these materials to optimize their effectiveness without compromising the device's structural integrity.

Balancing Mechanisms: Implement precision balancing mechanisms for moving parts, such as rotating heads or cutting components. A well-balanced design minimizes vibrations and ensures that the device operates smoothly, contributing to a quieter user experience. This involves meticulous engineering to achieve the desired balance, considering factors such as weight distribution and rotational symmetry.

Lubrication: Ensure that all moving parts within the electronic manicure device are adequately lubricated. Proper lubrication reduces friction between components, which can be a significant source of noise during operation. Select high-quality lubricants compatible with the device's materials and construction to enhance performance and minimize wear-related noise over time.

Variable Speed Settings: Incorporate a variable speed control feature into the device. This allows users to adjust the operating speed based on their specific needs. Lower speed settings are often associated with reduced noise levels while still maintaining effective functionality. Providing users with this flexibility enhances the versatility of the device and accommodates varying user preferences.

Enclosure Design: Optimize the design of the device enclosure to minimize the resonance of sound waves. This involves meticulous engineering to identify and address potential areas of acoustic resonance. By strategically shaping and structuring the device casing, manufacturers can mitigate the amplification of noise and create a more acoustically neutral environment.

Noise-Reducing Attachments: Design attachments and accessories with built-in noise-reducing features. For example, incorporate specialized materials or structures that absorb or dampen sound waves generated during specific manicure procedures. These attachments should seamlessly integrate with the main device, providing users with a comprehensive and quiet nail care experience.

Brushless Motors: Opt for brushless motors in the device's construction. Brushless motors, compared to their brushed counterparts, are inherently quieter due to the absence of physical brushes and commutators. Their smooth operation and reduced friction contribute to a quieter overall user experience. Implementing advanced motor technology aligns with the industry's pursuit of quieter and more efficient electronic manicure devices.

Electronic Noise Reduction: Integrate electronic noise reduction technologies into the device's circuitry. This may involve the use of advanced filtering techniques or shielding measures to minimize electromagnetic interference that can contribute to unwanted noise. By addressing electronic sources of noise, manufacturers can ensure a quieter and more refined operation of the electronic manicure device.

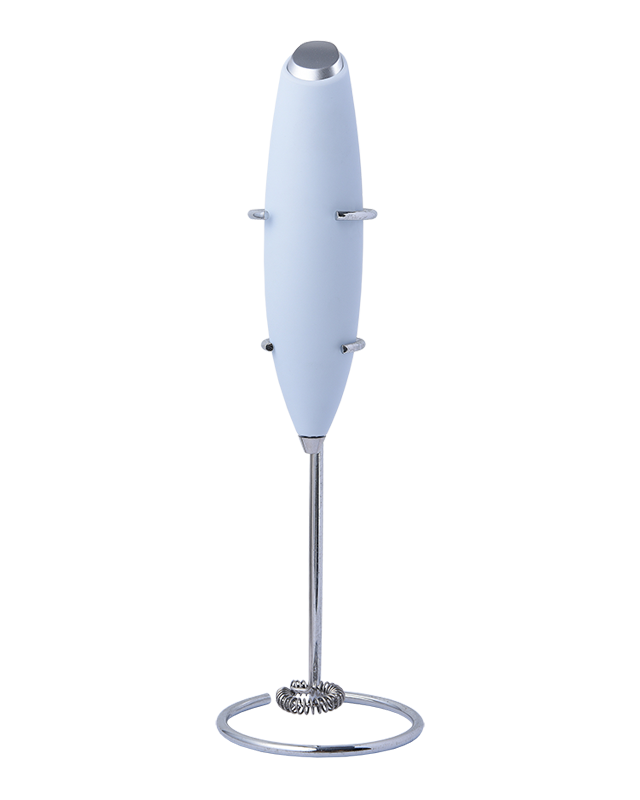

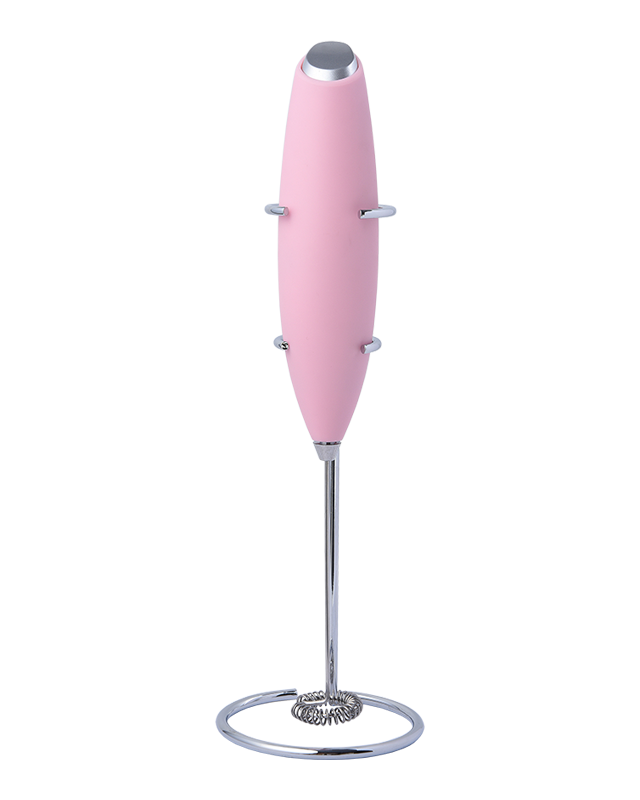

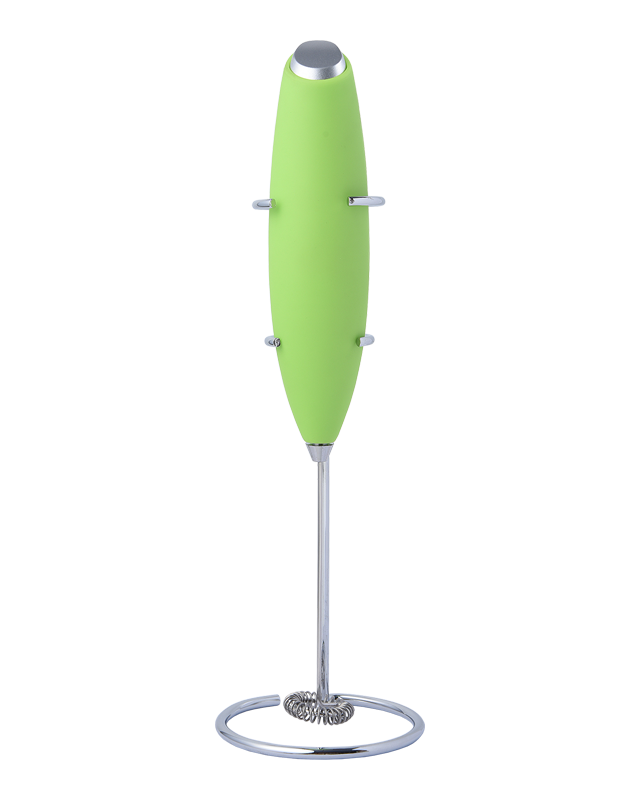

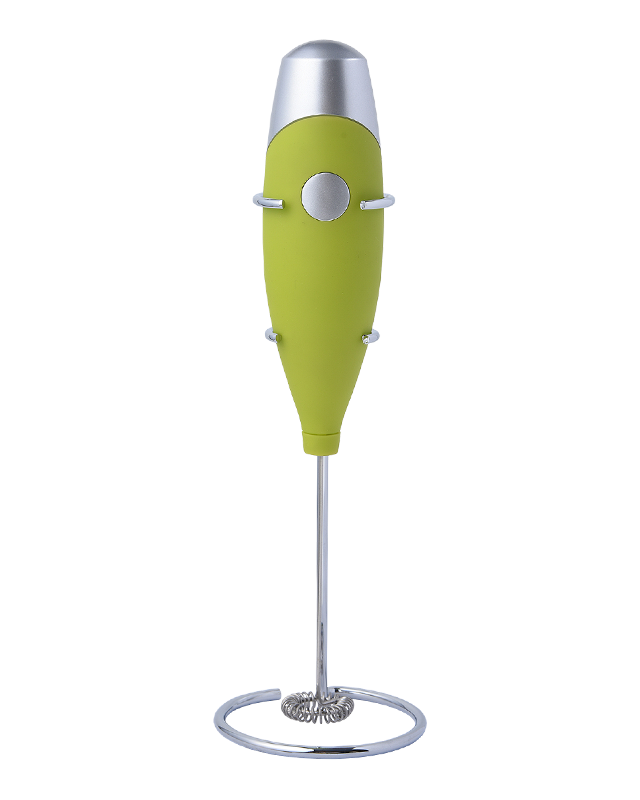

Manicure Sets EP-442

Manicure Sets EP-442

English

English

Français

Français

Español

Español

Deutsch

Deutsch

日本語

日本語