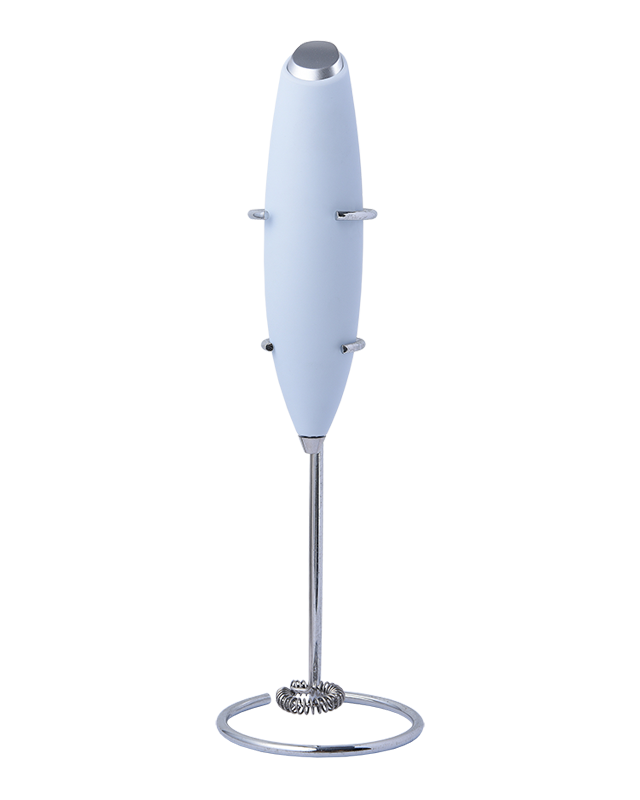

1. Ergonomic Design of the Frother Body and Handle

The design of the Battery Powered Electric Milk Frother begins with an ergonomic handle and body that ensure stable and secure operation during frothing. The handle is typically contoured to match natural hand anatomy, allowing the user to maintain a firm grip even if the hand becomes slightly wet or slippery. This secure grip reduces the risk of sudden tilting or unintentional shaking, which are the primary causes of splashing during frothing. Weight distribution is carefully considered so that the frother’s center of gravity aligns with the user’s hand, making it easier to hold steady for the duration of operation. Additionally, some models incorporate anti-slip materials, such as silicone or rubber coatings on the handle, which further enhance control. By focusing on ergonomics, manufacturers reduce hand fatigue and ensure that high-speed whisking does not inadvertently displace the container or cause milk to spill.

2. Whisk Geometry and Frothing Shaft Design

The frothing whisk and shaft are designed to maximize aeration while minimizing lateral milk displacement. Typically, the whisk consists of a coiled or looped wire attached to a narrow, vertically oriented shaft. The shaft is engineered to remain rigid and stable, preventing excessive wobbling during high-speed rotation. The whisk’s geometry is optimized to create a central vortex, drawing milk upward in a controlled spiral rather than outward toward the container edges. Some designs incorporate multiple loops or fine wire coils that evenly agitate the milk, producing dense, uniform foam while minimizing turbulence at the surface. By concentrating movement in the center and reducing chaotic lateral motion, the whisk ensures that milk rises vertically, forming a rich froth while remaining contained within the cup or jug. This careful combination of shaft rigidity and whisk design is essential for preventing splashing even when frothing cold or high-fat milk that tends to form unstable bubbles.

3. Controlled Motor Speed and Gradual Acceleration

A critical factor in splash prevention is the precise control of motor speed and acceleration. Many battery-powered frothers utilize brushless or high-efficiency DC motors with gradual ramp-up mechanisms. Instead of immediately spinning the whisk at full speed, the motor accelerates in stages, allowing the milk to establish a stable vortex before reaching maximum rotational speed. This approach reduces the turbulence that typically causes splashing when air is suddenly introduced into the milk. Furthermore, the motor is calibrated to maintain a consistent rotation rate, preventing oscillations or vibrations that could dislodge milk from the container. By combining gradual acceleration with stable high-speed operation, the frother ensures that milk flows upward smoothly and remains within the intended area, delivering consistent foam without creating a mess.

4. Container Depth, Shape, and Volume Guidelines

The choice of container significantly influences the risk of spillage when using a Battery Powered Electric Milk Frother. Manufacturers provide recommended container depths and volumes to ensure adequate space for milk expansion as foam forms. Users are advised to fill the container to no more than 75–80% of its total capacity, leaving a buffer at the top for froth growth. Tall, narrow containers are preferred because their walls guide the milk upward and contain the foam within a controlled space. Shallow or wide containers increase surface area, causing milk to spread and increasing the likelihood of splashing. Some frother kits include specialized cups designed with high walls and tapered openings to prevent milk from escaping while optimizing foam aeration. Adhering to these recommendations ensures that even vigorous frothing produces minimal mess and consistent foam volume.

5. Anti-Splash Attachments and Structural Features

To further reduce the risk of splattering, some Battery Powered Electric Milk Frothers incorporate anti-splash design elements. These may include guards around the whisk, tapered whisk tips, or smooth transitions between the shaft and the motor housing. The guards limit lateral projection of droplets, while the smooth whisk tip prevents milk from being ejected unpredictably when it hits the liquid surface. The frother’s shaft is often designed to minimize sudden disruptions in milk flow, keeping the movement vertical and centered. These features, combined with smooth container walls, help maintain a controlled vortex, preventing froth from spilling over even at maximum motor speed. Such attention to structural details enhances user confidence and reduces cleaning requirements, making the frother practical for daily use.

English

English

Français

Français

Español

Español

Deutsch

Deutsch

日本語

日本語